In the world of automotive performance tuning, particularly when dealing with aftermarket ECU systems, precise configuration is critical. For enthusiasts and professionals tuning the Nissan VQ35DE engine, which powers popular models like the Nissan 350Z, accurate engine timing is essential for extracting maximum power, improving fuel efficiency, and ensuring smooth operation. One key aspect of this tuning process is setting the link ecu vq35de trigger offset. The trigger offset directly influences the timing of ignition and fuel injection events, making it crucial for achieving optimal engine performance.

This article provides a detailed look at what trigger offset is, why it’s important for the VQ35DE engine, how to configure it within a Link ECU, and troubleshooting tips for any issues you may encounter. By the end of this guide, you’ll have the knowledge to confidently set the trigger offset and optimize your engine’s performance.

What is link ecu vq35de trigger offset?

Trigger offset refers to the angular difference between the actual position of the engine’s crankshaft and the position that the ECU interprets. In simpler terms, it defines the alignment between the physical timing of the engine and the signal received by the ECU. Since the link ecu vq35de trigger offset uses input from various sensors, including the crankshaft and camshaft position sensors, to determine when to fire the spark plugs and inject fuel, ensuring these sensors are properly calibrated is vital.

The concept of trigger offset is especially important in engines with multi-sensor setups, like the VQ35DE, which employs both crankshaft and camshaft position sensors for precise timing. In these engines, the ECU needs to know exactly when the crankshaft reaches certain positions relative to the camshaft(s) in order to fire the spark plugs at the correct time. If the trigger offset is incorrect, it can lead to misfires, poor fuel efficiency, and even engine damage if the timing is far enough off.

Understanding the VQ35DE Engine’s Trigger System

The VQ35DE engine utilizes a sophisticated trigger system that includes both crankshaft and camshaft position sensors. These sensors send signals to the ECU, allowing it to determine the correct ignition and injection timing. The crankshaft position sensor, for example, identifies the position of the crankshaft, while the camshaft position sensor monitors the timing of the intake and exhaust valves.

In the case of the VQ35DE engine, the trigger system is a multi-tooth system that allows the ECU to calculate the precise position of the crankshaft and camshafts. Understanding the function of these sensors is crucial when configuring the ECU’s trigger offset. The link ecu vq35de trigger offset uses a combination of crank and camshaft signals to determine the timing of ignition events. In the VQ35DE engine, the trigger setup typically involves:

- Crankshaft Position Sensor: This sensor provides feedback on the crankshaft’s position relative to the rest of the engine.

- Camshaft Position Sensors (for each camshaft): These sensors detect the position of the intake and exhaust camshafts.

- Variable Valve Timing (VVT) Sensors: On some configurations, VVT sensors help determine the optimal timing of the camshafts to adjust valve overlap for performance or fuel economy.

This trigger system’s accuracy is critical because any error in reading the crank or cam positions can lead to improper timing and significant performance loss. Hence, setting the right trigger offset is essential for smooth operation.

The Role of Trigger Offset in Timing Accuracy

Trigger offset has a direct impact on the timing of the engine’s ignition and fuel delivery. When the ECU receives the signal from the crankshaft and camshaft sensors, it uses this information to determine when to fire the spark plugs and inject fuel into the cylinders. The timing of these events must be precise to achieve optimal combustion and ensure that the engine operates efficiently.

If the trigger offset is too large or too small, the ECU may misinterpret the crank and cam signals, causing the timing to be incorrect. This miscalculation can lead to a variety of performance issues, such as:

- Engine Misfires: Incorrect timing can cause the spark plug to fire too early or too late, leading to misfires, reduced power, and rough engine operation.

- Poor Fuel Economy: Incorrect ignition timing can affect the efficiency of the combustion process, leading to increased fuel consumption.

- Damage to Engine Components: Over time, persistent timing errors can lead to excessive wear on engine components, including pistons, valves, and the camshaft, potentially resulting in expensive repairs.

Because the VQ35DE engine uses a combination of crank and cam sensors, it is crucial that the ECU interprets these signals accurately. Properly setting the trigger offset ensures that the ECU can correctly calculate the timing of ignition and fuel injection events, resulting in smoother engine performance and higher reliability.

How to Set the link ecu vq35de trigger offset

Configuring the trigger offset in a Link ECU is a straightforward process, but it requires careful attention to detail. If you are tuning a Nissan VQ35DE engine, follow these steps to correctly set the trigger offset in your Link ECU:

Step 1: Gather Necessary Equipment

Before beginning the setup process, ensure that you have all the necessary equipment, including:

- Link ECU: Ensure your Link ECU is installed and connected to the engine’s wiring harness.

- Crank and Cam Position Sensors: Verify that all relevant sensors are installed and functioning correctly.

- Laptop with Tuning Software: Ensure you have the Link ECU tuning software installed and ready to go.

- Timing Light or Strobe Light: A timing light is useful for verifying the ignition timing after the offset is set.

- Engine Specifications: You may need to refer to the VQ35DE engine’s manual or a reliable tuning guide to ensure you have the correct baseline settings.

Step 2: Initial ECU Setup

Before adjusting the trigger offset, ensure that the link ecu vq35de trigger offsetengine. This includes setting up the base parameters such as:

- Crank and Cam Sensor Inputs: Ensure that the ECU is receiving signals from the crankshaft and camshaft position sensors.

- Variable Valve Timing (VVT): If applicable, configure the VVT settings to match the engine’s specifications.

- Ignition Timing: Set the initial ignition timing to the manufacturer’s recommendations before making adjustments to the trigger offset.

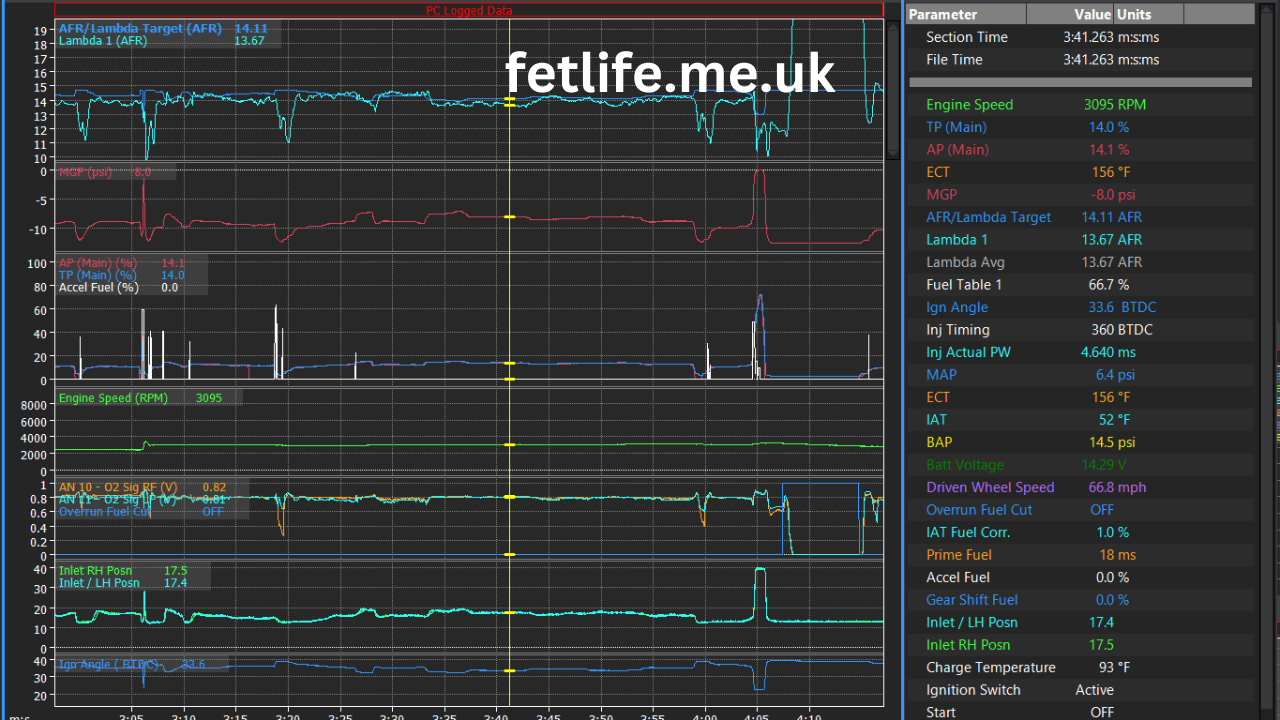

Step 3: Perform a Cam Angle Test

One of the most reliable methods for determining the trigger offset is performing a cam angle test. This test involves running the engine and recording the camshaft position while adjusting the trigger offset until the readings match the engine’s timing.

- Set the Timing Light: Attach the timing light or strobe light to the engine to monitor the crankshaft’s timing.

- Run the Engine: Start the engine and allow it to idle at a steady RPM.

- Adjust the Trigger Offset: In the Link ECU software, access the trigger offset settings and begin adjusting the value.

- Observe the Timing: As you adjust the trigger offset, use the timing light to observe the engine’s ignition timing. Your goal is to adjust the offset so that the ECU’s calculations align with the physical position of the crankshaft.

- Record the Offset Value: Once the timing is correct, record the offset value displayed in the ECU software.

Step 4: Save and Test the Settings

After adjusting the trigger offset and verifying the ignition timing, save your settings within the ECU software. Perform a test run of the engine to ensure that it operates smoothly and that no misfires or performance issues occur.

Troubleshooting Common Trigger Offset Issues

While setting the trigger offset is generally straightforward, there are some common issues that can arise during the process. Here are a few troubleshooting tips for resolving these problems:

1. Incorrect Timing at Idle or High RPM link ecu vq35de trigger offset

If the ignition timing is off at either idle or high RPM, it could indicate that the trigger offset is still incorrect. Double-check the offset value and perform another cam angle test to ensure accuracy.

Previous article; Ricky Fitzpatrick son A Story of Music, Woodworking, and Fatherhood

2. Engine Misfires or Stalling

Engine misfires or stalling at specific RPMs may indicate a miscalculated trigger offset. In this case, recheck the trigger settings and ensure that both the crank and cam sensors are functioning correctly.

3. Trigger Errors in ECU Logs

If the ECU logs indicate trigger errors, such as “missing teeth” or “crank/cam sync issues,” it may suggest that the trigger offset is not properly aligned with the engine’s actual timing. Consult the ECU’s diagnostic tools to check for any sensor malfunctions or wiring issues.

4. Unstable Idle

An unstable or rough idle can sometimes be traced back to an incorrectly set trigger offset. Verify that the offset value is properly adjusted and that the engine is receiving accurate timing signals from the crank and cam sensors.

Conclusion

Configuring the link ecu vq35de trigger offsetfor the Nissan VQ35DE engine is an essential step in tuning for optimal performance. By setting the trigger offset correctly, you ensure that the ECU can accurately calculate ignition and fuel injection timing, leading to smoother engine operation, better power output, and improved fuel efficiency.

The process involves verifying the sensor connections, performing a cam angle test, and adjusting the offset value until the timing is correct. Always test the engine after making changes to ensure that it runs smoothly and that no performance issues arise.

If you encounter issues along the way, troubleshooting common problems such as timing errors or engine misfires will help resolve most issues. With careful attention to detail and proper tuning, you can achieve optimal performance from your VQ35DE engine and fully utilize the power of your Link ECU.

4o mini

O